Dorothy – 19/3/99

If you haven’t already, you may wish to read

part 1 in this series.

Beech harvesting – the preliminary trials

Visits to Waituna and Slaty Creek Rob explained some of the processes involved in beech harvesting and to let

us see the results of the trials took us to sites at Waipuna and Slaty Creek.

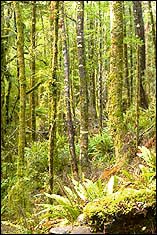

What we saw Waipuna Rob took us to a site at Waipuna on a fertile river flat where the forest

was mainly red and silver beech with some kahikatea. It had been clear-felled some eighty years ago which meant that the trees were of a

fairly uniform size.

Regeneration of sites such as this is profuse with up to 20,000 beech seedlings per hectare common. Competition is fierce and probably only about

2% of the seedlings will reach the pole stage (Canopy height 25+ metres,

20-60cms diameter). Even at this stage, competition-induced stress is often

severe enough that the weakened forest often becomes susceptible to drought

and insect attack. Such attack can result in total collapse of the forest

structure.

Trees under stress give off chemicals which attract the male beetles. They

give off pheromone which attracts the females which lay eggs that mature in

two to three years. The beetles carry fungi and the holes they create give

the fungi access to the trees. They in turn block the vessels in the tree

clogging the movement of fluid, and ultimately killing the tree.

Thinning by old style harvesting methods One possible answer to collapse of the forest is to reduce competition and

create more space by thinning or removing some of the trees. However, when

this was tried with horses, tractors, and skidders the problems of access

led led to a high level of damage to the retained trees, poor hygiene leading to pinhole attack and destabilisation through induced windthrow.

This meant that the trees that were retained would frequently collapse after the thinning.

Helicopter thinning A much more effective option is to use a small helicopter for selective

thinning to give space. This involves very low use of roading, has insignificant on-ground effects, and ensures that remaining seedlings and

poles are untouched. In this method trees that are removed are felled so

that they fall into natural gaps, and the logs are removed vertically. Branches and trimmings that are over 15 centimetres in diameter are cut

into small lengths so that they will dry or decay more quickly and not offer sites for the pinhole beetle.

|

|

| Waipuna Trial – Interior view of forest following thinning Photo source TWC |

Eighteen hectares were thinned in a trial area in November 1995. Before

thinning began the forest was measured intensively. 12% of the total volume of poles of saleable dimension was taken. Even though there has

been no indication of negative effects, Timberlands has opted for a conservative maximum removal of 10% of volume in its sustainable management

plans for such ‘recovery’ forests. The abundant remaining poles are growing

well, given more light by the thinning process.

The largest trees were retained as to remove these with their large spreading crowns would damage surrounding trees during felling. These trees

will also be retained to form the ‘old age’ component of the developing

forest. Thinning results in the forest once again being made up of trees

of different ages with younger trees having the chance to grow.

Had the removal of the trees not been pointed out we would not have noticed

it.

|

|

| Stump treated to deter the pinhole beetle Photo source Peter Hunt |

We looked at a stump where the pinhole beetles were at the larval stage.

The method of controlling them was to make a plunge cut in the stump and

apply urea. Water collecting in the cut raises the wood moisture content,

and this with the urea encourages fungi to invade and grow within the stump. This makes conditions unlivable for the pinhole larvae and they ultimately die. Finally litter from the forest floor was spread on top of

the stump.

Regeneration occurs around the stumps. Some seedlings grow on coarse woody

debris (CWD) left after logging. The raised site is often beneficial for

regeneration as it lifts the seedlings above the competing fern. The CWD

also helps maintain the forest floor micro-climate, thereby maintaining a

healthy environment for native plants and invertebrates.

|

|

| Waipuna Trial – Regeneration of red beech on a raised site, a tree stump Photo source TWC |

The survival of the Prince of Wales fern, which is very susceptible to desiccation, is a good indicator that forest floor temperature and humidity

has been effectively unchanged. It was abundant at the site we were viewing.

|

|

| Prince of Wales fern Photo source Peter Hunt |

Slaty Creek This is the site of the first trial for the new method of beech group selection harvesting. An average of three or four trees is taken from each

site.

There are all ages of trees here as unlike the forest that was logged eighty years ago this is unmodified forest. The logging here was done two

years ago, and with this method poles, saplings and seedlings are all coming on. Prince of Wales fern is abundant and healthy. We would have

had difficulty identifying it as a logging site as the stumps were mossed

and the beech seedlings and undergrowth were abundant – a total contrast

from the sites we were accustomed to seeing after harvesting by the old

method.

The harvesting process A model is developed determining how many of what species and of what size

can be taken.

The forester then knows how many he can take, picks the site, selects the

trees from the list, and puts a tag on them.

The Global Positioning System is used and the feller has a map to enable

him to find the tagged tree. It is his final decision as to whether the

tree can be felled safely and without damage to surrounding trees. He may

refuse. Once the tree is felled the tag is nailed back on the stump. The stump is treated as described above as beetles are quick to bore into

freshly felled timber.

The tree is recorded in the register for auditing.

The tree is cut into logs which are the right weight for the helicopter,

and organised to give the biggest load possible. The helicopter uses a scissor-type grapple which tightens on the logs as it lifts them. A square of white plastic is attached to the log to indicate the grapple point. Two squares indicate that two logs are tied together: three indicate three logs.

The helicopter transports the logs to the landing where they are trimmed,

cut to the appropriate length, graded, put on a truck and transported to

the mill.

Beech utilisation Beech wood has traditionally been regarded by the saw milling industry as

inferior to rimu. This was not due to the inherent properties of beech wood, but because the timber is more difficult to saw and dry, and because

it has higher levels of internal defects such as knots, pinhole, rots, and

staining.

Research done by Timberlands has shown that the timber is at least as high

a quality as rimu provided care is taken during drying. Often it is air

dried for six months and then finished in a kiln. The drying process varies with the species of beech.

Millers see a problem in the long return on the cash outlay and the fact

that there is less clear wood from the trees. Earlier millers preferred

rimu because it was easier to work with. There is a strong demand world

wide for high quality hardwood timbers such as beech, and Timberlands is

working on the challenge of developing suitable markets both here and abroad.

Beech timber is harder than rimu and stronger. There is an excellent range

of colours and it makes superb flooring panelling, joinery and furniture.

Comparison between roading for aerial logging and uphill to ridge tops

where roads are highly visible Conventional systems involve cable logging uphill. Where these hauling

systems involved up to twenty eight lineal metres of road per hectare, helicopter logging involves around three to four lineal metres per hectare.

Helicopter logging is also almost exclusively downhill, which means that

the low impact roads are located in valley bottoms where they are generally

visible only from an elevated position.

Facilities provided for tourists These roads are a recreational asset opening up the forests to visitors.

Bark covered helicopter pads and sites for parking are provided, making the

forests attractive to tourists, trampers, mountain bikers and hunters.

My questions about future plans for beech production Are beech plantations to be established? There are no plans for the establishment of beech plantations which will be

thinned and pruned as under sustainable management such intervention will

not be tolerated.

Are beech logs to be chipped for the chipboard market? Beech is regarded as a specialty timber to be used for its beauty and its

strength, not for the chip market.

Read Part 3 of the articles on Timberlands next week to see how the SOE

is undertaking research into the ecology of the forests under its management.